Yingkou Qingying Petrochemical Equipment Co., Ltd

Marketing department: manager Guo

Mobile: 18641771136

Purchasing department: Manager Zhu

Mobile: 13050617889

Address: No. 58, South Binhai Road, Xishi District, Yingkou, Liaoning, China

The catalytic cracking unit process ranks first in the secondary processing of petroleum:

Crude oil is often vacuum distilled to obtain light oil products such as gasoline and diesel, but the yield is only 10% to 40%. And some light oils are not of high quality. with industrial development. Internal combustion engines place higher requirements on the quantity and quality of light oil. This demand has prompted the refining industry to develop secondary crude oil processing to further increase the depth of crude oil processing, obtain more light oil products, and improve their quality. Catalytic cracking satisfies and realizes the conversion of heavy oil into gasoline and diesel and the like. Therefore, catalytic cracking is the last important secondary process in the refining industry.

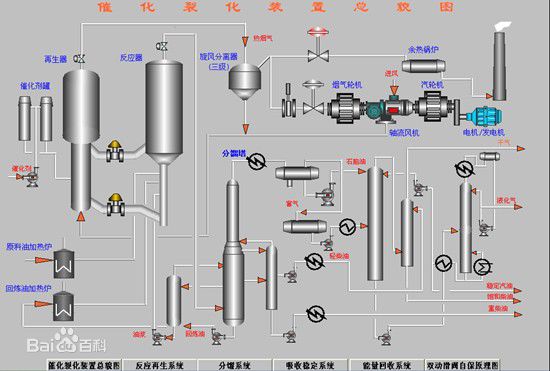

The development of catalytic cracking technology is closely dependent on the development of catalysts. With the microsphere catalyst, the fluidized bed catalytic cracking unit appeared; the appearance of the molecular sieve catalyst led to the development of the riser catalytic cracking. Product yield, product quality, and economic benefits have a significant impact. Catalytic cracking unit usually consists of three parts, namely reaction-regeneration system, fractionation system and absorption stabilization system.