Yingkou Qingying Petrochemical Equipment Co., Ltd

Marketing department: manager Guo

Mobile: 18641771136

Purchasing department: Manager Zhu

Mobile: 13050617889

Address: No. 58, South Binhai Road, Xishi District, Yingkou, Liaoning, China

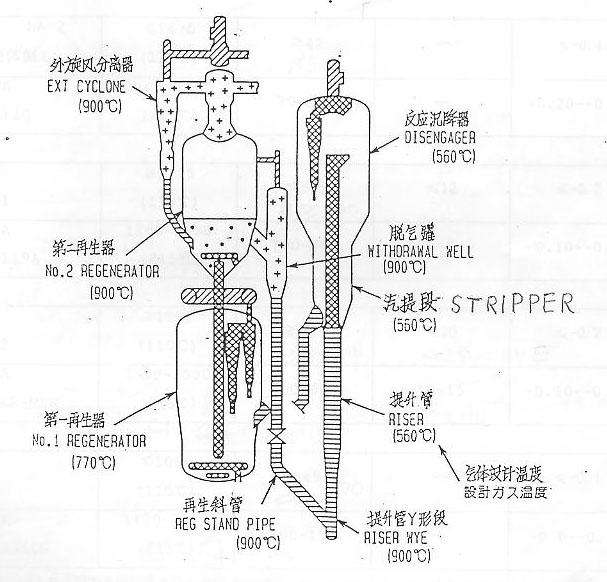

Typical catalytic cracking fractionation system. The reaction product (oil and gas) from the reactor enters the fractionation tower from the bottom, and is divided into several intermediate products in the fractionation section after the desuperheating section at the bottom: the top of the tower is rich gas and gasoline, and the side line has light diesel oil, heavy diesel oil and return gas. oil refining. The bottom product is an oil slurry. Light diesel oil and heavy diesel oil are stripped respectively, and then discharged from the device after heat exchange and cooling.

The fractional distillation column of the catalytic cracking unit has several characteristics:

①The feed is superheated oil and gas with catalyst dust. Therefore, there is a desuperheating section at the bottom of the fractionation tower. The cooled oil slurry is used to cool the oil and gas to a saturated state and wash off the entrained dust for fractionation and to avoid clogging of the tray.

②The residual heat of the whole tower is large and the separation accuracy requirements of the products are relatively easy to meet. Therefore, there are generally multiple circulating refluxes: circulating reflux at the top of the tower, 1-2 circulating refluxes in the middle section and oil slurry circulation.

③ The top of the tower adopts circulating reflux instead of cold reflux. The main reason is that the oil and gas entering the fractionation tower contains a considerable amount of inert gas and non-condensable gas, which will affect the effect of the condensing cooler at the top of the column; the use of circulating reflux instead of cold reflux Reflux can reduce the pressure drop from the top of the fractionation column to the inlet of the compressor, thereby increasing the inlet pressure of the compressor and reducing the power consumption of the compressor.